Easy to Control

The sensitive 7” capacitive touchscreen enables easy operation even with laboratory gloves.

Enhancing PCR Efficiency and Accuracy

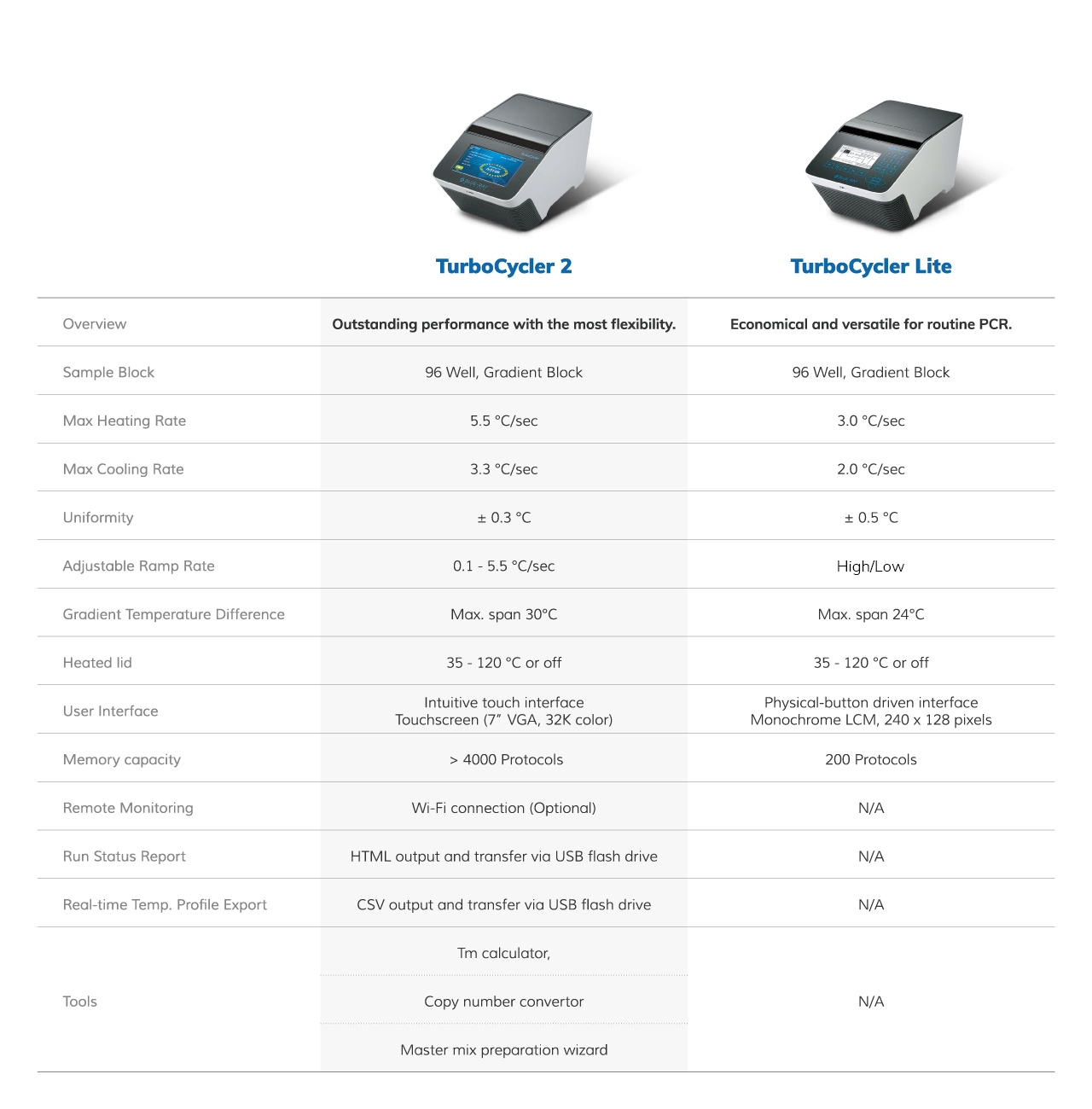

TurboCycler 2 thermal cycler is designed specifically to enhance PCR efficiency and accuracy. It is equipped with a 7” sensitive touchscreen and a friendly graphic user interface, which makes operation highly intuitive. With flexible ramp rate and gradient temperature control, TurboCycler 2 greatly increases PCR accurate optimization. The Wi-Fi function enables you to monitor the PCR run status anytime remotely with walk-away convenience.

Flexible Ramp Rate Control

from 0.1 - 5.5 ℃/sec to meet the need for the CRISPR related assays .Fully Adjustable Lid Temperature

can be set between 35 and 120 °C for virtually any type of experiment including NGS pre-treatment.Gradient Optimization

range from 1 to 30 °C enables optimal experimental conditions in a single PCR run.

The sensitive 7” capacitive touchscreen enables easy operation even with laboratory gloves.

The graphic interface is easy to use, making the adjustment of experiment parameters such as temperature, time and cycle quick and simple.

Monitor your PCR status remotely anytime on your mobile device via the free TurboApp.

* Specifications are subject to change without prior notice.

The low-profile PCR vessel design reduces the overhead space above the reaction solution inside the vessel.

During thermal cycling, water in the solutions evaporates and fills the overhead space. This causes a concentration increase in the reacting solution.

The smaller the overhead space, the smaller the amount of evaporated water and concentration change in the solution. This is especially helpful when low volume reaction mixtures are being used.

In general, the low-profile PCR vessels are 5 mm shorter in height than the regular PCR vessels.

Use the compressor mat and set the lid heat to 120°C to maintain the pressure in the vessels.

Lid heating is used to avoid severe condensation in the PCR tubes during the reaction.

The amount of evaporation is related to the sealing of the PCR vessels. A firm pressure on the lid will help maintain the integrity of the seal and prevent evaporation.

The Lid heating does not cycle and the competitive units do not cycle either.

When the block temperature drops below 30°C, lid heating is turned off and the temperature of lid decreases gradually. Competitive units also do this.

Condensation inside the tube is caused by the temperature difference between the tube and the cycler. The tube temperature might remain at 4°C for a long time at the end of a run. This happens with all cyclers. It is like a bottle of water being put into a refrigerator; water always condenses in the neck.

The amount of water lost to the environment from a reaction vessel by evaporation depends on the integrity of the seal.

If the seal or the vessel cannot withstand the temperature cycling during the run, there may be deformation. This deformation may be serious enough to tear off the seal. Plates and seals of poor quality may deform enough to disrupt the seal. Low quality consumables should be avoided. It is essential that the plates and seals remain undeformed for the entire run.

The lid of the cycler needs to be heated to the proper temperature before the block starts to heat.

The delay will depend on the lid temperature setting, the room temperature, and how the compression mat has been used. Heating of the lid usually takes between 2 to 8 minutes.

When the power comes back on again after a “power-failure-during-a-run” event, the unit will start up and continue where it had stopped and run until the end of the protocol. This will happen as long as the power switch has not been touched in the meantime.

Also, if the power stays off for a long time, there will be a short delay (after the power comes back on) before the unit starts again. This is because it might take a minute or two for the lid to get back up to the right temperature.

After the lid module reaches its setting temperature, the protocol will be continued. This “Auto-restart after power outage” function has been specifically designed to protect the PCR experiment.

Yes! But we do not recommend this be done very often.

Running your cycler overnight at 4°C can potentially reduce the life cycle of the instrument. In most applications, 16°C instead of 4°C for overnight storage can protect your DNA sample very well.

Yes! The ramping rate of TurboCycler 2 can be adjusted from 0.1°C to 5.5°C.

There are three different temperature settings for the lid:

1. 120°C (for use with low-profile vessel + compression mat), with an extra 3 minutes of pre-heat

2. 105°C

3. Heater off

There is only one block configuration for the TurboCycler Lite and TurboCycler 2 so far. They are not interchangeable.

However, if the block needs to be serviced it can removed and sent back to our factory for service.

The storage limits are:

-Protocol: >4000 sets

-History: 50 sets

-User folder: 100 sets

When the storage of protocols has reached the limit, a message will remind the user to delete some protocols. The system will not overwrite existing protocols.

However, when history storage reaches the limit, new histories will over-write the oldest. But the user can set a reminder that shows when history storage gets close to the limit.

-Block mode: Enables system operation with maximum temperature control based on the actual block temperature regardless of the sample temperature. This mode is designed to mimic the control algorithm used in most early model thermal cyclers.

-Sample mode: Enables system operation with simulated temperature control. Users are required to input the sample volume: 5-100μl. In this mode, the temperature control algorithm will estimate the sample temperature based on the block temperature and sample volume. This is the mode recommended for normal operation.